- Solar Energy Systems[10]

- Camping Lights[3]

- Emergency Lights[1]

- Wall Lamps[1]

- Garden Lights[5]

- Street Lights[4]

- Other Lights & Lighting Products[8]

- Lawn Lamps[6]

- LED Flashlights[4]

- Flashlights & Torches[3]

- Traffic Light[2]

- Traffic Signal[1]

- Mobile Phone Chargers[3]

- Solar Chargers[6]

- Backpacks[5]

- Road Stud[6]

- Other Roadway Products[1]

- Other Metals & Metal Products[5]

- Other Wires[1]

- Other Solar Energy Related Products[7]

- Other Aluminum[1]

- Aluminum Profiles[8]

- Badges[1]

- Alarm[5]

- Self Defense Supplies[1]

- Contact Person : Mr. Qi John

- Company Name : Shenzhen Sveck Technology Co., Ltd.

- Tel : 86-0755-2794 5800

- Fax : 86-0755-2263 3040

- Address : Guangdong,Shenzhen,NO.5,DaYang Industrial Zone, GongMing Town, BAO'AN, SHENZHEN, CHINA. 518106

- Country/Region : China

- Zip : 518101

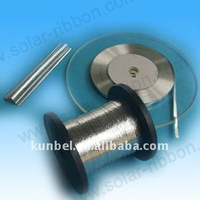

Tinned-Copper Ribbon

PV Ribbon; Photovoltaic Ribbon;Solar PV Ribbon;PV Ribbon; Welding Strip; Interlinked Strip; Busbar; Copper Base Strip;solar photovoltaic solder;PV Ribbon; Interconnector; Tinned-Copper Ribbon; ECO-Friendly Photovoltaic Ribbon.1.Factory Price,High Quality2.Material:Oxygen-free copper3.Meet EU ROHS Standard

**********************************

Specification:PV Ribbon; Photovoltaic Ribbon;Solar PV Ribbon;PV Ribbon; Welding Strip; Interlinked Strip; Busbar; Copper Base Strip;solar photovoltaic solder;PV Ribbon; Interconnector; Tinned-Copper Ribbon; ECO-Friendly Photovoltaic Ribbon.

Product Application:Apply to Solar cell connection, electric & electro-circuit mending connection.

Product Features:

1. Raw material

(1) copper matrix: Select high-purity T2 copper(resistance0.0174μΩ·m), by using nice slitter and perfect annealing process makes our products low resistivity, high scalability and low rate of fragment in the mean time.

(2) tin alloy: The specialized formula solders material(melting point 183°C- 227°C),ensures not only chemistry with better electrode, but also great physics characteristic. The product is highly resistant to creep, fatigue and high temperature. It ensures high reliability of better works.

(3) soldering fluxes :non-cleaning flux with low solid content is strictly used, and no halogen elements is contained, It won’t tum yellow or black in high temperature and high-humidity experiment.

2. Appearance

The tin copper strip has good surface finish and uniform color. There’s no defects such as copper-leakage, Tin-remove black spot, corrosion, crack, scar and so on.

3. Dimension tolerance

Thickness on thickness:±0.05mm

Tolerances on width: ±0.05mm

4. Curving:≤5mm/1000mm

5. Coating

Coating composition:lead-free:96.5%Sn3.5%Ag/99%sn1%Ag

Lead-contain:62%Sn36%Pb2%Ag

Thickness of coating: ≥0.02mm(single)

6. Tensile strength: >20kg/mm2

7.Extensibility:Interconnected ribbon≥25%,bus-bar ≥15%

8. Packing and storage

Packing: Fixed-length the tin-coated copper strip:3-layer

Package: wooden box +corrugated cardboard box + thermoplastic film

Unfixes- length the tin-coated copper strip:2-layer

Package: wooden box +corrugated cardboard box or plastic spool +thermoplastic film

Tinned-Copper Ribbon